#shower-curtain #buen-chancho #rigging #breaktests #double-blakes-hitch #friction-hitch

# Tensioning Highline Curtain Rods: Beyond the Clutch

The shower curtain, or buen chancho system of highline rigging has become a staple of rigging big lines. Invented by Slackline Canarias and shared widely in 2019, the practice has allowed smaller crews to rig bigger lines by reducing the amount of pulling power needed, and significantly reduced the strain on tag lines. The shower curtain system typically involves having an extra tensioned tagline, called the “curtain rod,” that the highline is periodically attached to with pulleys. The curtain rod separates the force from the weight of the highline from the force of pulling by holding the highline’s weight, making it much easier to pull across. Because the curtain line needs to be low stretch and low friction, Ultra High Molecular Weight Polyethylene (UHMWPE, also known by the brand name Dyneema) is the material of choice, with 4mm being the most common diameter. While UHMWPE functions very well as a curtain rod, the main difficulty with it is finding a way to tension it.

The tighter a curtain rod is, the easier it is to pull the highline across it. This is because there is less uphill pulling and less weight that needs to be supported by the tagline. But tensioning a thin UHMWPE cord is very difficult. Traditional rope gripping methods like toothed or cammed ascenders, hitch cords, and progress capture pulleys either don’t grip properly or easily damage the UHMWPE. This led to the development of a number of techniques that workaround the limitation of the slippery curtain, including simply attaching a static rope to one end of the curtain rod to enable tensioning with normal methods of tensioning ropes. But by far the most commonly used has been the clutch. A clutch is a short piece of UHMWPE with a fixed eye on one end that the curtain gets spliced into. The curtain gets buried 12-18 inches into the clutch, and it looks and functions similarly to a whoopie sling. This allows you to grip the curtain anywhere along its length, pull tension, and then when the curtain is anchored in place the clutch can be moved. The difference between a clutch and a whoopie sling is that on a whoopie both strands are coupled to share tension easily, which results in a more stable grip. This difference in loading means that while clutches can hold tension very well, they are very sensitive to anything touching the loose front. Even slight pressure on the front can cause them to slip under tension. In addition to the risk of slipping, clutches also can’t be added or removed while the curtain is rigged, so they require careful planning of where the curtain will need to be tensioned. They also tend to gum over time when used with a curtain rod that has a coating, which can be a major hassle during a rig.

Given the numerous issues with clutches, it is time to thank them for the lines rigged with them and move on. Whatever replaces clutches should be resistant to accidental slipping, easy to add or remove at any time and anywhere on the curtain, and should be as light and strong as a clutch. Luckily, the replacement that satisfies all of these conditions is here.

# Friction Hitches

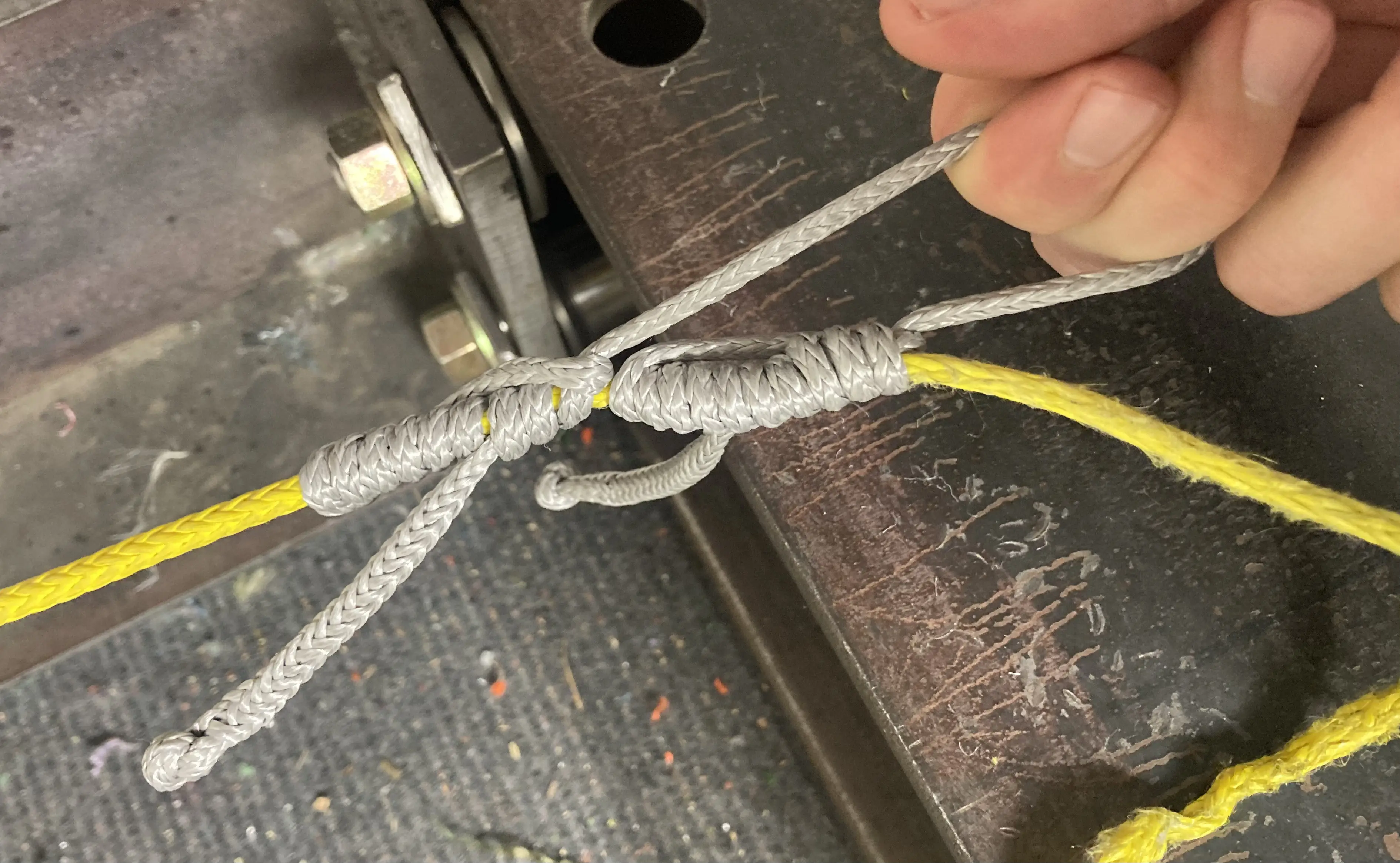

While planning the “Absurdian” 3K project Pierce Kenji mentioned he had been testing a few different friction hitches as a way of replacing clutches. Instead of tying the friction hitch with standard hitch cord, he was using 3mm Amsteel. While matching two very slippery materials together is unintuitive for a “friction hitch”, it worked the best in his testing. Using 2.5 mm Amsteel on 4 mm curtain rod, he was able to break test a 6 wrap prusik up to 7 kN, breaking the curtain. He then tested various other knots up to 4 kN to see what held consistently, and tested 2.5 mm, 3 mm, and 4mm amsteel for the hitch cord. He tested French prusiks (autoblocks), swabisch, distel, and Blakes hitches, and found the best performer was a double Blakes hitch in 3mm cord. The double Blakes hitch involves tying a Blakes hitch with each tail of the 3mm cord, with both Blakes hitches pointing the same direction, and then loading the connecting strand between the hitches. The Blakes he was tying had 6 wraps for each Blakes, and the tail went back under the first two wraps, which I will abbreviate as a 6/2 Blakes. We were able to stress test this double Blakes method when we rigged a shakedown 1.1 km line in Bend, Oregon before the 3K project. It handled well enough that we decided to use the double Blakes instead of clutches on the 3K.

At the 3K we quickly ran into the slip limits of the double Blakes around 4 kN, which was right at the peak that Pierce tested to. We were able to solve this by connecting two different double Blakes together to equalize them. With this double double Blakes method we were able to pull up to 7 kN on the curtain. We pulled to 7 kN so that it would settle to 5 kN before sending webbing, which in hindsight put us unnecessarily close to the limits of the curtain. In theory, the two double Blakes together would slip around 8 kN, but we were far beyond the scope of the testing that had been done. We tensioned the curtain from both anchors, and one side had more troubles with slipping then the other. In general it worked well though, allowing us to add and remove the tensioning system whenever we wanted. The grip worked well enough that we also used the double Blakes as part of the curtain termination while sending the webbing. We were quite nervous when loading the double double Blakes to 7 kN however, and were eager to see how close to the limits of the system we were.

# Testing

Recently, I was able to break test a few different friction hitches on curtain rod with Jerry Miszewski on the Balance Community break test machine. This was exploratory testing, where we did not repeat tests that did not look promising. The full breaktests can be found in [breaktests]. We tested the 6/2 double Blakes we used on the 3K and it slipped at 4.1 kN. We tried tying the curtain in a knot behind the double Blakes to see if back tension helped prevent the slippage, and it held until 4.8 kN but then continued to slip. When we tried the double double Blakes hitch, which is two double Blakes hitches equalized together, it slipped at 6 kN instead of the 7 we were able to achieve at the 3K.

Curious to see if other hitches worked as well, we tested a 5 wrap prussic, a Valdotain Tresse, and a combination of a Blakes hitch and Valdotain Tresse I came up with. The prussic slipped at 3.6, the Valdotain Tresse at 3.3, and the Blakes/Valdotain Tresse combo at 3.8. Since none of these improved on the double Blakes, we stopped testing alternative hitches and tried to improve on the holding power of the Blakes Hitch instead.

Following the theory that more wraps translates to more friction, we tried an 8/3 double Blakes and it slipped at 5.2 kN. Since that showed improvement, we tried even more wraps with a 10/4 double Blakes and it broke the curtain at 7.7 kN. This was a significant improvement, and since we had been reusing the curtain between tests and it was visibly damaged, we repeated the test with a fresh piece of curtain. With new curtain, the 10/4 double Blakes broke at 9.2 kN which is over half the 16 kN MBS of the curtain. Thinking we could reduce the strain on the curtain at the start of the hitch to increase the breaking strength, we tried a double Blakes where the front Blakes hitch was an 8/3, and the rear was a 10/4. This broke the curtain at 8 kN, indicating there isn’t an advantage to mixing different variants of the Blakes hitch in a double Blakes. Given the testing we did, we were content that a 10/4 double Blakes is close to optimal for 3mm Amsteel friction hitches on 4mm curtain rods. It would be good to do further testing to determine a statistically significant breaking strength for the 10/4 Blakes hitch.

# Comparison to Clutches

There is surprisingly little data on clutches. There is one video from Ryan Jenks that has a single break test of a 5mm clutch. With a 33" bury it breaks at 17.1 kN, or 71% of 5mm Amsteel’s 24 kN MBS. I have tested one 28" bury 4mm clutch on a 4mm UHMWPE curtain and it broke at 12 kN, or 75% of the curtain’s 16 kN MBS. The testing for both systems is rather limited, but clutches seem significantly stronger at ~70% of the curtain MBS compared to the double Blakes which only gets ~55% of the curtain MBS. At the upper limits of curtain rigging that does add quite a bit to the safety factor, but those high tensions are only on the double Blakes during tensioning. When the webbing is being sent on the curtain, which is when the forces on the curtain are highest, the curtain is anchored with another system.

Double Blakes more than make up for their lower strength in usability. They can easily be added or removed at any point in the curtain, even under significant tension. Clutches must be spliced in place, and depending on how far your curtain anchor is from the end of a splice may need to be fed up to 100m to be put in a usable position. It is much easier to tie a double Blakes exactly where its needed, do any necessary tensioning, and then remove it. If you forget a clutch, or it gets stuck in place during rigging (this has happened to me), there is very little you can do. But its possible to tie a double Blakes with the tail of the curtain and tension with it. There isn’t any published testing about matched diameter double Blakes, but in a pinch it will allow you to at least put some tension on the curtain. To me the usability of the double Blakes far outweighs the loss in strength compared to the clutch.

# How to Use the 10/4 Blakes

To make the hitch cord, cut 42" of 3mm amsteel. Then tie an overhand knot 3" from each end of the Amsteel, and bury the ends on the outsides of the overhand back on the inside edge of the overhand. This makes it less likely for the tails to slip out over time.

To tie the double Blakes, take one end and wrap it ten times around the curtain, wrapping towards the gap and away from the anchor. Then bring the end back and pass it under the first four wraps, again moving towards the gap and away from the anchor. See the Animated Knots on how to tie a Blakes hitchfor visual reference of a 4/2 Blakes hitch. Pull the tails on each side of the knot to set it, and you have one Blakes hitch. Repeat the same steps on the other end to make the other Blakes hitch. Make sure both Blakes hitches wrap the same way, going from the anchor towards the gap. You want at least 3" of tail coming out of each Blakes hitch, which should match the amount of reburied amsteel. Load the loop in between the 2 knots to tension.

One of the benefits of the double Blakes hitch is it can easily be moved along the curtain when it isn’t loaded. It will however be harder to move after being tensioned, so the first step to moving it is to feed some tail back into the knot to loosen it. Then slide the hitches in either direction by pushing either the front or back of the hitch. You may need to move one hitch at a time. Before loading it again, make sure there’s still at 3" of tail coming out of each hitch, as the tails can easily get shorter while moving the knot. Finally pull the tails on each side of each Blakes hitch to set the knots again, and it is ready to load again.

To undo the knot, loosen it by pushing the tails into the knot. If it’s really set, it may need some massaging to come undone. Once it’s loose, untie each Blakes hitch and the cord will be totally freed from the curtain.

# Breaktests

| Knot | Variant | Slip/Break | Force (kN) | Notes |

|---|---|---|---|---|

| Prussic | 5 wraps | Slip | ||

| Double Blakes | 6/2 | Slip | 4.1 | |

| Double Blakes | 6/2 | Slip | 4.82 | With stopper knot, on used curtain from prior test |

| Valdotain Tresse | 8 wraps 4 crosses | Slip | 3.29 | On used curtain from prior test |

| Blakes/Valdotain Tresse | 8 wraps 4 crosses | Slip | 3.83 | On used curtain from prior test |

| Double Blakes | 8/3 | Slip | 5.16 | On used curtain from prior test |

| Double Blakes | 10/4 | Break | 7.71 | On used curtain from prior test |

| Double Blakes | 10/4 | Break | 9.21 | |

| Double Blakes | 8/3, 10/4 | Break | 8.00 | Front Blakes 8/3, rear Blakes 10/4 |

| Double Double Blakes | 6/2 | Slip | 6.01 | 2 double Blakes equalized with soft shackle |

# Conclusion

Friction hitches offer significant improvements over clutches for tensioning curtains. They can be added and removed at any point, and do not become stuck like clutches. They are also less sensitive to slipping from forward pressure, since they tighten at the front of the hitch. While they are weaker than clutches, they still have plenty of safety factor for most use cases and their ease of use more than makes up for their lower strength.

Of the friction hitches tested so far, the 10/4 double Blakes does the best. While other friction hitches slip, it breaks the curtain at 8.5 kN or around 55% of the curtain’s MBS. If you are dealing with lower tensions, or want a solution that slips without breaking the curtain, an 8/3 double Blakes will slip at around 5.5 kN. A 42" piece of 3mm Amsteel long enough to tie the 10/4 double Blakes weighs only 9 grams, and costs roughly $2 USD. Making a couple hitch cords and adding them to your highline kit will give you a flexible solution to deal with curtain rigging problems.